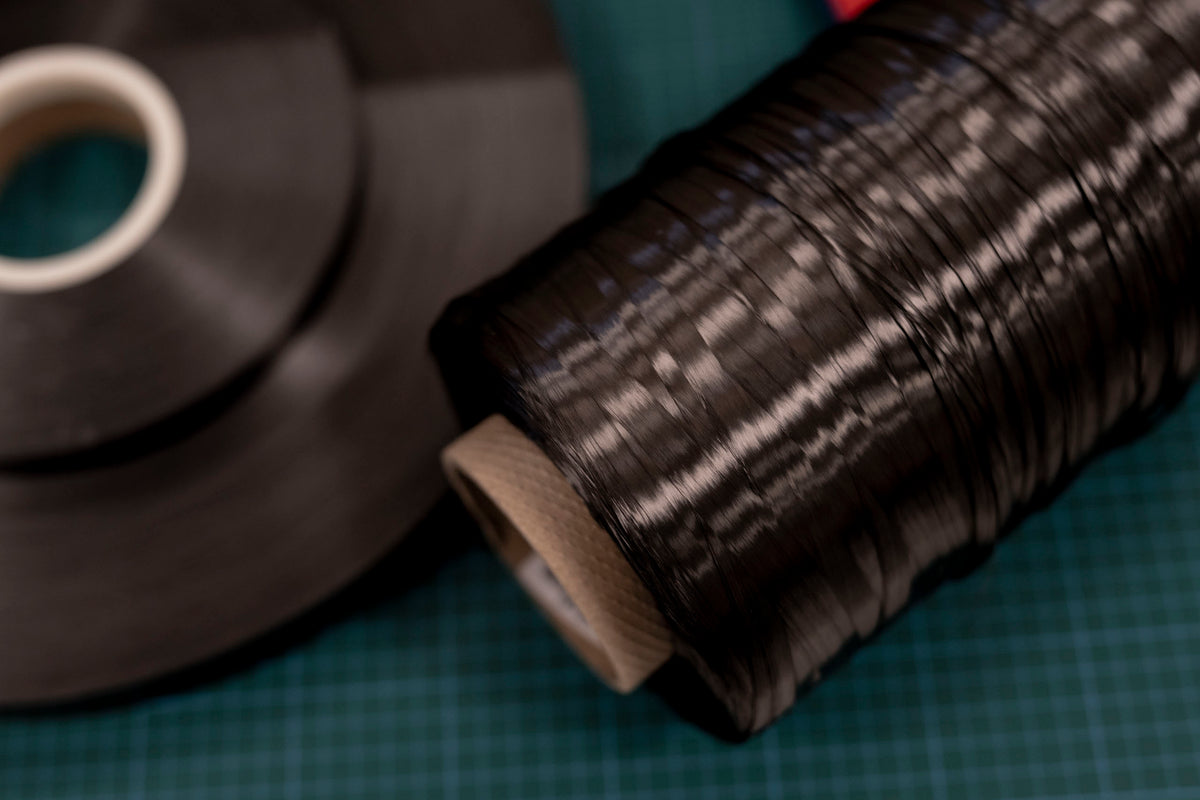

Since 2017, we have been collaborating with Microwave Chemical Co., Ltd. to develop an innovative carbon fiber production technology using microwave technology. This cutting-edge approach is expected to reduce the overall energy consumption by approximately 50 %, leading to a lower CO₂ footprint of PAN-based carbon fibers compared to traditional methods, without compromising performance. Our pilot production line has been operational since January 2024, where evaluations are currently underway. We anticipate commencing commercial operations in 2027.

If you are interested in our eco-friendly produced carbon fiber for one of the targeted applications, please don’t hesitate to contact us. We are eager to discuss your specific requirements and will soon be able to provide material samples. Be among the first to experience this innovative product.

The mobility and industrial landscape are evolving. Hydrogen pressure vessels are crucial in this new era of industrial production and mobility, whether for trucks, trains, or even aircraft. We are committed to making future mobility more sustainable by supplying eco-friendly produced carbon fibers for the filament winding of type IV and V pressure vessels.

Wind turbines are pivotal in the transition to renewable energy. To meet the growing demand for energy, these turbines are being constructed with increasingly larger rotor diameters. Traditional glass fiber-reinforced composites are no longer sufficient, making the use of carbon fibers essential for future wind turbines. We aim to contribute to sustainable energy production by providing eco-friendly produced carbon fibers for rotor blade manufacturing.

Since the 1970s, carbon fibers have been integral to aircraft construction, with some modern aircraft comprising over 50 % carbon fiber-reinforced polymer (CFRP). Sustainable aviation now depends not only on lightweight construction but also on the use of the most sustainable materials possible. This is where our eco-friendly produced carbon fiber comes in, which we are aiming to supply as a grade specifically for the aerospace industry.