Fused Granular Fabrication (FGF) is an additive manufacturing technique that utilizes unreinforced or reinforced thermoplastic pellets as its primary material. This method provides numerous benefits, particularly in the realm of large-format additive manufacturing (LFAM). FGF is experiencing rapid growth across various industries and has become a leading technology for producing components such as boat hulls and molds for concrete or composite manufacturing. TAFNEX™ Compound, available in a specialized grade for FGF, unlocks vast potential for creating high-performance components suitable for diverse environments.

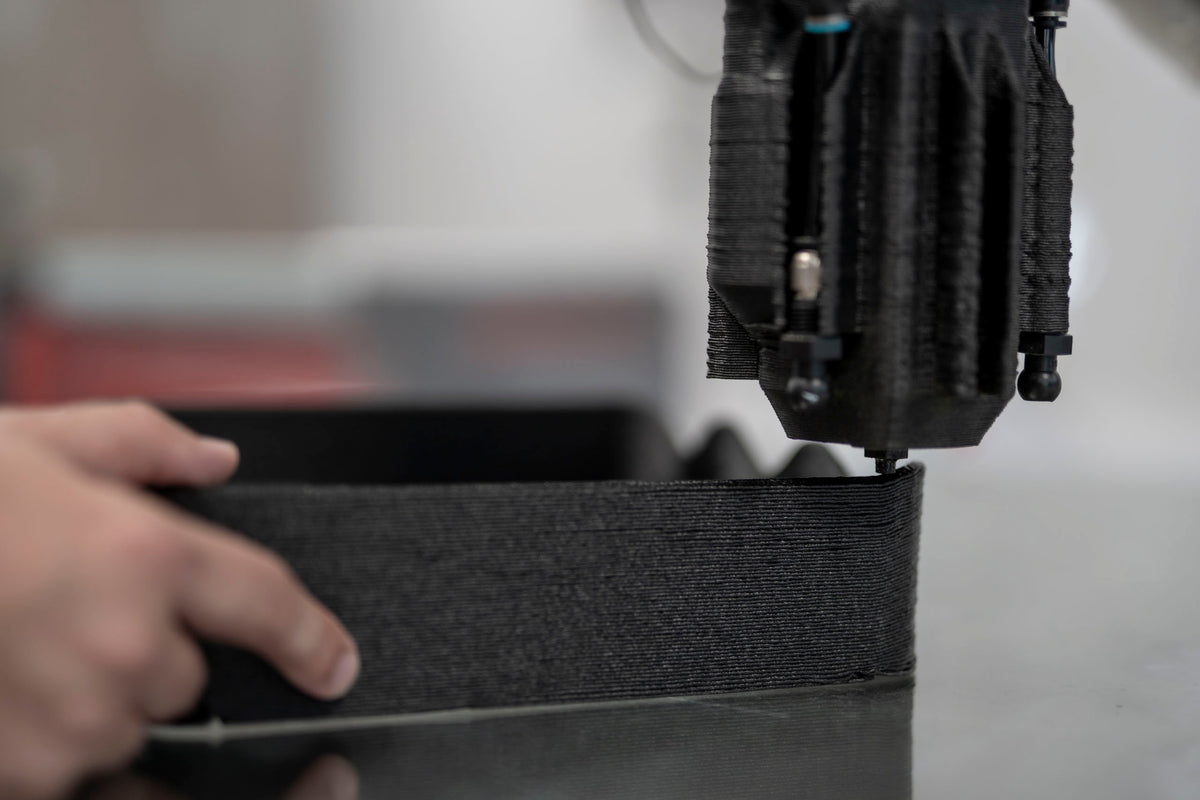

FGF is essentially a mobile version of conventional plastic extrusion, using a typical extruder mounted on a robot or gantry system. Dry pellets are fed into a hopper and moved by an extrusion screw through multiple heating zones, where they melt before being extruded. Controlled by pressure within the extruder, this process follows the contours defined by the software, applying material layer by layer along the component's geometry. The process, depending on the material, is conducted in a sealed, temperature-controlled chamber to ensure layer adhesion, and the printing bed is often temperature-regulated as well. Mechanical post-processing is typically required after FGF manufacturing to achieve smooth surfaces. Some manufacturers provide systems that integrate both additive manufacturing via FGF and subsequent subtractive processes in a single cell.