Injection Molding is the most common method for manufacturing plastic parts, particularly for complex shapes. Injection Molding can also be utilized to manufacture “hybrid thermoplastic composite” components by integrating continuous fiber-reinforced inserts. This process is often referred to as Composite Overmolding. TAFNEX™ UD Tape can be used as local reinforcement at critical locations, reducing overall wall thickness and thereby material consumption. Additionally, it is possible to manufacture high-performance composite components by using TAFNEX™ Structural Sheets or Sandwich Panels as reinforcing inserts. These sheets or panels are formed into shape beforehand or within within the mold, while functionalization is added through the injected polypropylene (PP) material, e.g., TAFNEX™ Compound. Due to high investment costs, injection molding is primarily used for large-volume productions.

The process varies depending on the type of TAFNEX™ insert used and whether the insert needs to be formed. While the process for using TAFNEX™ UD Tape closely resembles regular Injection Molding, using a sheet or tailored blank insert requires additional peripheral machinery to form the insert within the mold. Learn more below.

This overmolding process can be employed if the insert is flexible enough to be formed without being heated above its melting point, or if the insert does not need to be formed at all. TAFNEX™ UD Tape is sufficiently flexible for up to two or three layers, depending on the forming radius/curvature.

1. Positioning the insert in the open mold

2. Closing the mold

3. Injection/overmolding

4. Opening the mold

5. Demolding

This overmolding process is used when the insert needs to be heated above its melting point to be formed into the desired shape. This applies to all TAFNEX™ Sheets and tailored blanks with more than two or three layers, depending on the forming radius/curvature.

1. Heating the insert above its melting point

2. Positioning the insert in the open mold

3. Closing the mold + forming

4. Consolidation + injection/overmolding

5. Opening the mold

6. Demolding

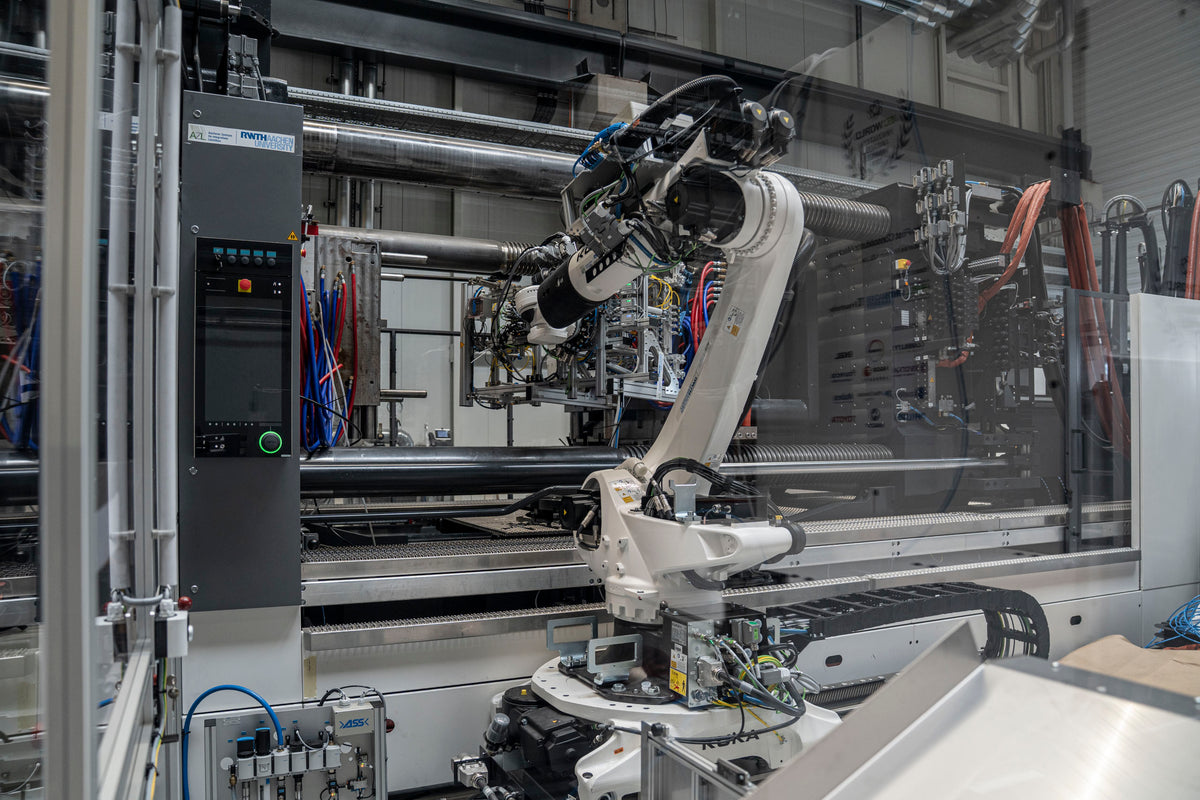

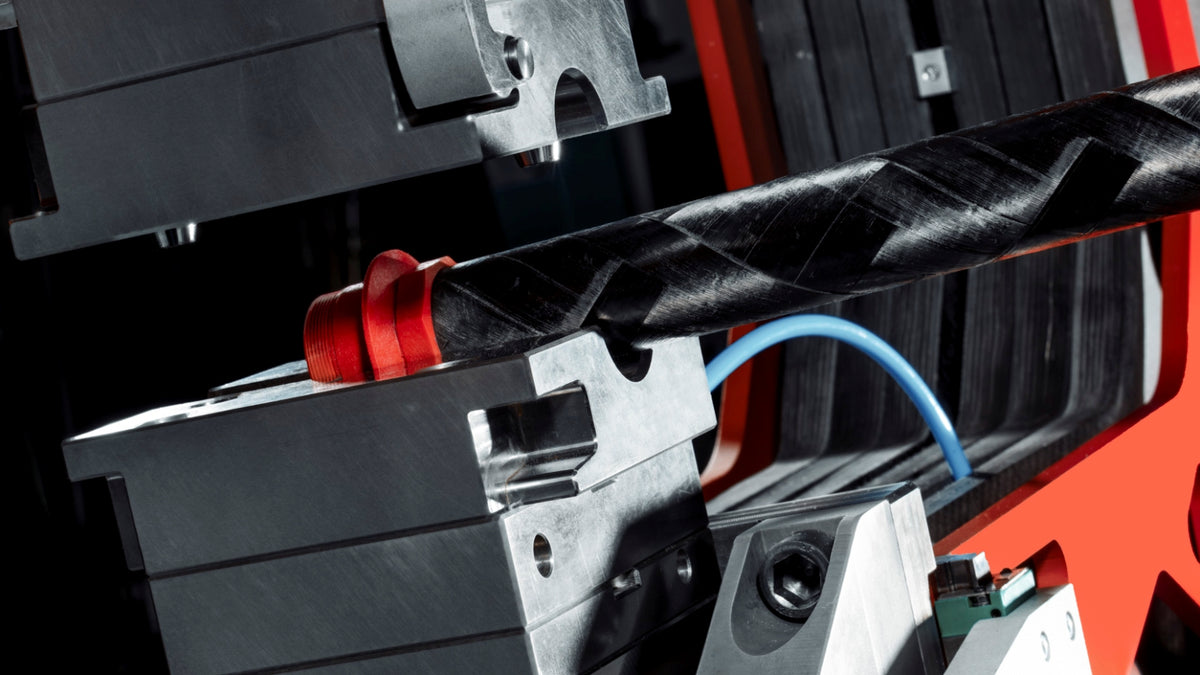

TAFNEX™ Tubes can be functionalized using the previously mentioned Composite Overmolding technologies with standard Injection Molding machinery. However, there is also the option to utilize a novel technology: Robotized Injection Molding. This mobile Injection Molding machinery from ANYBRID GmbH allows for the functionalization of TAFNEX™ Tubes immediately after the Tape Winding process. Based on the specific application, either a robotic arm or a gantry system is employed. Further exploration of this technology for industrial use is currently underway as part of the WI-IN research project.