Style and performance in perfect sync

Introducing TAFNEX™ Woven Sheet

TAFNEX™ Woven Sheets are made by weaving slit tape into a specific pattern, followed by a pressing step to consolidate the structure. By design, each woven layer comprises two crossed layers of tape. Find out more about the possible designs and specifications below.

High degree of customization

Exemplary weaving designs

Alternative option

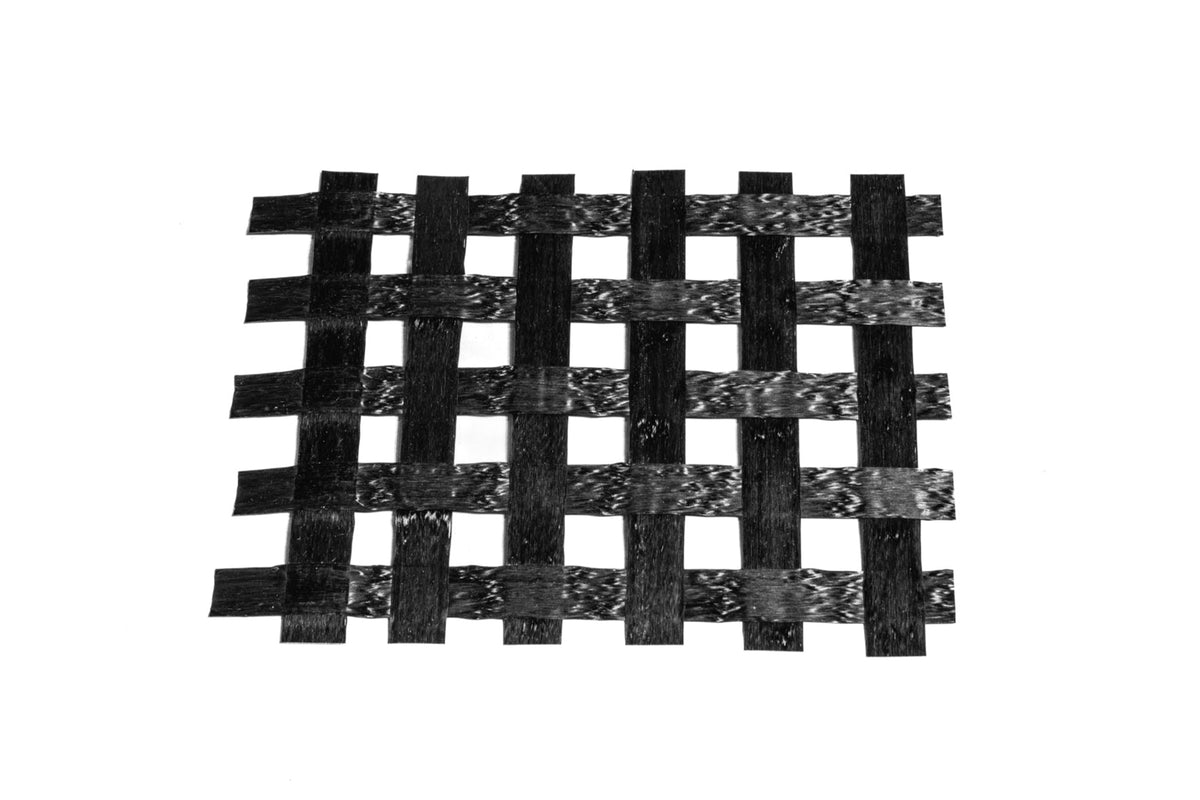

Lattice reinforcement structure

Weaving TAFNEX™ UD Tape allows for the creation of not just fully reinforced TAFNEX™ Woven Sheets but also reinforcing lattice structures. The adaptability of grid spacing enables customization of this reinforcing structure for specific applications. The lattice structure can be utilized directly in the manufacturing process or pre-laminated onto a full-surface sheet, e.g., made from PP-GF.

Which production methods can transform TAFNEX™ Woven Sheets into functional components?

Exemplary use cases