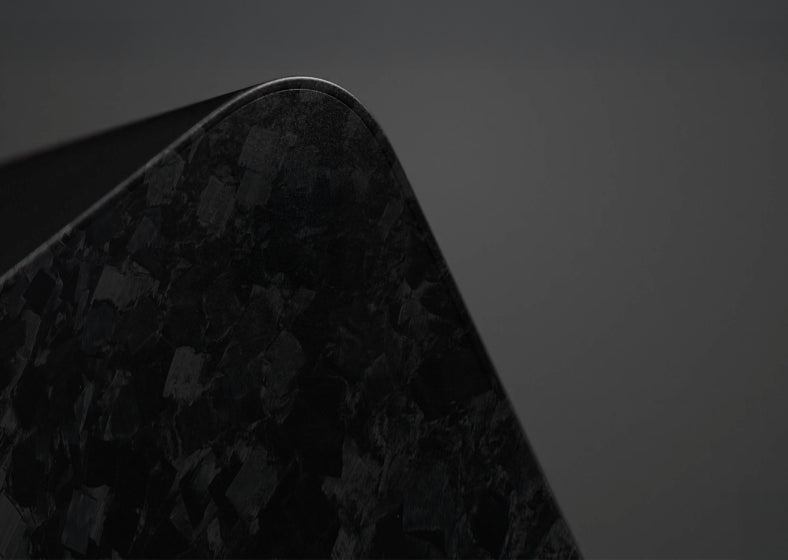

TAFNEX™ is an advanced thermoplastic carbon fiber material known for its lightweight properties and easy recyclability. Its exceptional processing flexibility enables the production of various drone components, including two different types of drone blades. High-performance drone blades made from TAFNEX™ Sandwich Panels provide significant benefits over traditional thermoset carbon composite blades. For smaller UAVs, injection-molded drone blades using TAFNEX™ Compound offer a cost-effective solution, with the added benefit of lighter blades achievable through reinforcement with TAFNEX™ UD Tape.

High-performance drone blades are produced by Thermoforming a TAFNEX™ Sandwich Panel with a foam core. In this process, the foam core and carbon fiber composite skin are usually integrated together rather than beforehand.

By utilizing low-density foam cores, the resulting drone blades are exceptionally lightweight yet capable of enduring the forces and environmental conditions they encounter.

TAFNEX™ Drone blades, made entirely from thermoplastic materials, respond to crashes with plastic deformations rather than brittle failure. This results in very small debris that disperses over a minimal area. Additionally, the fracture surfaces are not sharp-edged, making these blades significantly safer for people nearby in the event of an accident compared to thermoset carbon drone blades.

Learn more about the test results below.

Detailed comparison of how TAFNEX™ Drone blades and state-of-the-art thermoset composite propellers behave under failure conditions.

Illustration of the mechanical recycling journey for TAFNEX™ Drone blades.

Side-by-side performance review of TAFNEX™ Drone blades and state-of-the-art thermoset composite propellers, highlighting differences in thrust and power usage.

An in-depth, step-by-step breakdown of the TAFNEX™ Drone blade production process, highlighting key stages with technical details.

In addition to press forming, TAFNEX™ Drone blades can be produced via Injection Molding using a TAFNEX™ Compound, which can include in-situ foaming. Ideal for high-volume production, this method also enables advanced design features – such as integrated leading-edge serrations for noise reduction.

The injection-molded blade's mechanical performance can be boosted, if required, by adding local or full reinforcement with TAFNEX™ UD Tape.

Visual explanation of the noise-reduction effects of serrated leading edges on drone propellers.